When it comes to establishing reliable and high-performance network or telecommunication connections, the choice of connector is paramount. The landscape of connectivity hardware is vast, but Molex Standard Modular Jacks stand out as a benchmark for versatility and quality. These components, often referred to as RJ-style connectors, are not a one-size-fits-all solution. Understanding the key differences between various modular jacks is essential for engineers, designers, and technicians aiming to optimize their systems for performance, durability, and cost-effectiveness. This comparison will delve into the critical distinctions that define the ideal connector for any given application.

Shielding Showdown: Metal vs. Plastic Modular Jacks

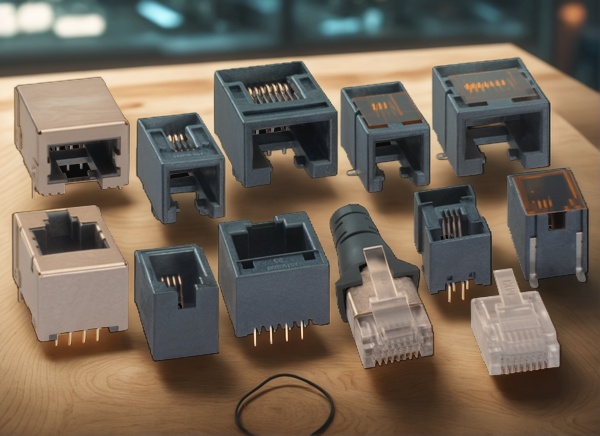

One of the most significant differentiators among Modular Jack Types is the construction of their housing, specifically whether they are shielded or unshielded. Metal-shielded modular jacks are engineered with a robust metal casing that surrounds the connector. This design provides critical protection against electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring signal integrity in environments with high electronic noise, such as factory floors, medical facilities, or dense data centers. In contrast, unshielded jacks, typically made with an all-plastic body, are a more lightweight and cost-effective option. They are perfectly suitable for controlled environments like homes or standard offices where EMI is not a primary concern. The choice here is a direct trade-off between the need for environmental resilience and the constraints of component cost and weight.

Density and Design: Single-Port vs. Multi-Port Configurations

Another crucial point of comparison is the port configuration. Single-port jacks are the most common type, designed to accommodate a single cable connection. They are ideal for end-user devices like laptops, desktop computers, and single-line telephones where space is dedicated to one connection point. Their simplicity and small footprint make them a universal choice for countless applications. On the other hand, multi-port modular jacks, which can be ganged (side-by-side) or stacked (one above the other), are designed for high-density applications. Network switches, routers, and patch panels heavily rely on these configurations to maximize the number of connections within a limited physical footprint on the printed circuit board (PCB). A stacked multi-port jack, for instance, can double the connection density without increasing the required PCB real estate, making it a critical component for enterprise-grade networking hardware.

Inside the Connection: Contact Plating and Keying Mechanisms

Beyond the external housing and port count, the internal features of a modular jack dictate its performance and reliability over time. Contact plating is a primary example. Many standard jacks use tin plating, which offers adequate performance for basic, low-cycle applications. However, for high-speed data transmission or systems requiring long-term reliability, gold-plated contacts are superior. Gold provides excellent conductivity and is highly resistant to corrosion and oxidation, preventing signal degradation over thousands of mating cycles. Furthermore, variations in keying and orientation differentiate Modular Jack Types for specific uses. While most jacks follow a standard pinout, some are designed with unique keying mechanisms or reversed orientations to prevent accidental misconnections in complex systems, adding a layer of safety and ensuring that specific cables are plugged into their intended ports.

Choosing the Right Modular Jack for Your Application

In conclusion, selecting the appropriate modular jack involves a careful evaluation of competing features. The decision between a metal-shielded and an unshielded jack hinges on the electronic environment and the required level of signal protection. The choice between a single-port and a multi-port configuration is driven by the required connection density and available space on the board. Finally, internal features like gold plating determine the level of performance and long-term reliability you can expect from the connection. A comprehensive portfolio, such as the one offered with Molex Standard Modular Jacks, provides tailored solutions for this entire spectrum of needs. By understanding these fundamental comparisons, you can confidently select a connector that not only fits your design but also enhances its overall functionality and longevity.